This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

FullCut

RODICUT standard covers with the advantages of inner flexible fiber and knuckle system (no bolts) are now upgraded meeting the current request of customers:

- Improvement in the quality of the die cutting process

- Easier mounting and dismounting processes

- Longer lifetime

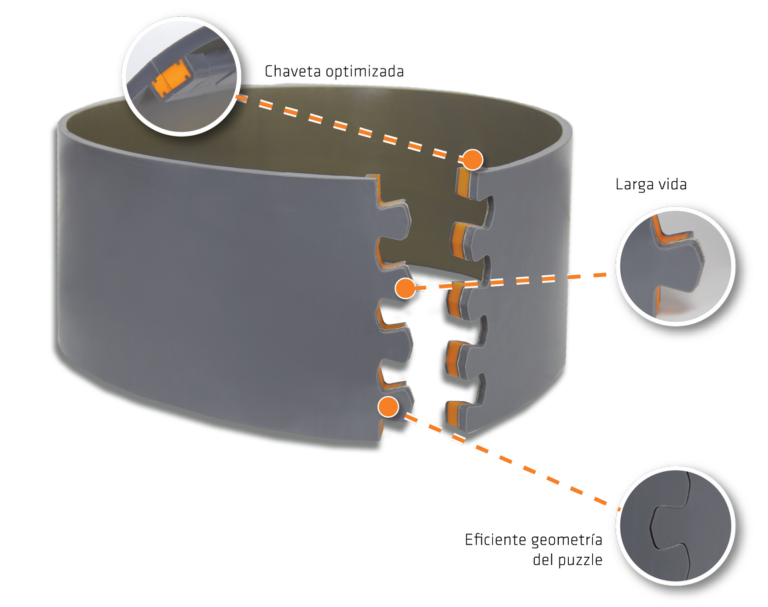

The result of a careful study of improvement needs for the rotary die cutting process has resulted in the modernization of our most successful product: FULLCUT/LONGLIFE innovation.

The anvil covers with optimized slot to avoid “spring effect”, efficient joint geometry for better support, easier installation, and with the longest lifetime.

Efficient joint geometry:

- Long life

- Optimized slot

Here is a brief explanation of the 3 elements, similar to the reverse of the sheet:

- Optimized Slot: Minimized working pressure

- Increased cardboard processing quality

- Reduction of fatigue in rotary dies

- Less rotation time: easy assembly-disassembly operation

Long-life anvil: Longer life is achieved thanks to the combination of 3 causes:

- Less knife penetration

- Tear resistance special formula

- Facility for frequent rotation