This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

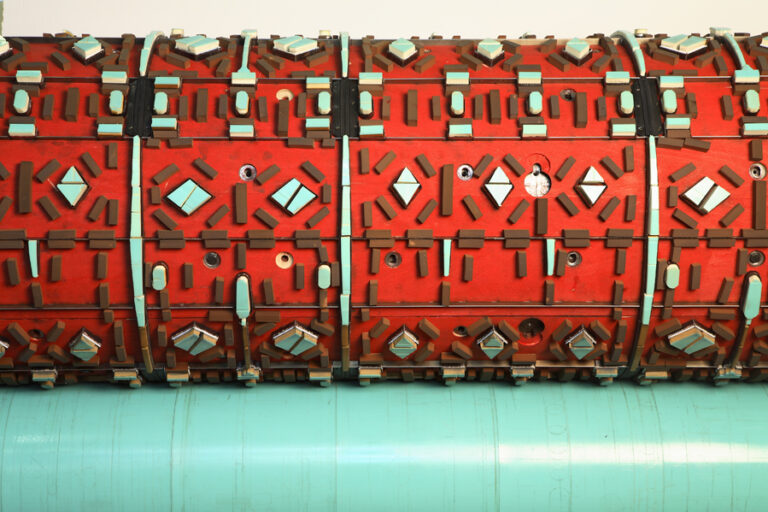

Rotary cutting dies and material

After more than 40 years of experience manufacturing rotary cutting dies with the latest technologies, a thorough understanding of the customer’s needs, and new packaging designs, RODICUT – TOOLS is a clear market leader in the manufacture of high-quality rotary cutting dies.

- Specialised technical personnel devoted to the design of the dies, and a consultancy service tailored to your needs.

- High quality materials and an optimum level of stocks that guarantees immediate production.

- Different types of rules, either centrally or laterally edged, depending on the working conditions and the needs of the client.

- Innovation with new materials offering new features.

- Experience with types of cutting dies incorporating new ejection technologies (e.g. Mitsubishi).

- State of the art technology and qualified professionals with a wide experience in the field.

- Fulfillment of all commitments agreed upon with the customer, knowing that respecting the delivery date is key in order to meet the customer’s needs.

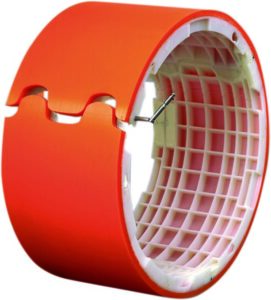

All of this, together with our broad experience with polyurethane, allows us to innovate and create new exclusive elements for rotary cutting dies, such as:

- Rubbers with a polyurethane layer that helps eject inner waste, especially in high-printing work, preventing waste products from sticking to the rubber

- Exclusive spiked system for gluing boxes, especially those of the double- double corrugated board.

- Male-female protective stops for blades.

HAVING IT ALL IS NOT ENOUGH….MAINTENANCE IS THE KEY … We have developed a series of preventive Maintenance Programs for rotary cutting dies.

THE IMPORTANCE OF LEARNING: TRAINING PROGRAMS FOR OPERATORS.

To those customers who already have their own workshops, we can offer our technical assistance and consultancy services (design, counsel on new models, guidance in complicated projects…). Moreover, we offer a whole range of additional products and materials for their use:

- CURVED WOOD, RULES for CUTTING, CREASING, PERFORATING, CUT-CREASING.

- EJECTION and GUIDING rubbers, KUSHION CREASE, INTERMEDIATE RUBBER FOR CREASING (1/4 UNCUT)

- SPIKED gluing plates.

- LEATHER HAMMERS (traditional type) or PU HAMMERS (longer lasting). Also, ALUMINIUM HOOPS (Posilock system) or CLAMPING BARS (Texo)

- TOOLS such as TONGS (blade removal), SHEARS, CUTTERS, GOUGES, WRENCHES, ROTALIN, PNEUMATIC DRILLS, SCREWS, WASHERS, BLADE PROTECTORS, MALE/FEMALE STOPS, etc.

- TOOLS AND EQUIPMENT FOR DIEMAKING WORKSHOPS (Benders, Rule Cutter, Notchers machines…)

- Any other replacement you may need.